Looking to learn what capacity management is? Then you’ve landed in the right place!

Humans are capable of many things, but we all have our limits as well.

We can certainly eat two slices of cake within minutes. A whole cake? Well, we might be able to eat that as well. But, how about 10 cakes? That’s just impossible for most of us.

This can be used as an example to understand the capacity of the human body. For a business, capacity refers to the total amount of final goods it can manufacture in a given period of time.

It basically helps you determine how much work your company can take on and how fast it can grow. It’s one of the most critical aspects of a business.

Despite it being such an important aspect, very few businesses know what exactly it is and how to calculate it, therefore resulting in its mismanagement or the lack of its management.

This leads to the wastage of resources, money, and effort. For this very reason, it’s crucial that your business follow a well-defined capacity management process.

No idea what capacity management is? Don’t worry, we’ve got you covered!

In this blog, we will help you understand what exactly capacity management is, why it is beneficial for the success of a business, and the processes involved in implementing one!

Ready? Let’s get started!

What is Capacity Management? (Definition)

Capacity management is a strategy used by businesses to manage production output depending on the demand and supply conditions in the market so that resources are used optimally.

Basically, it ensures that a business has the resources in place to meet its current and future needs. It answers questions like:

- Do you have sufficient available resources to cover all your projects?

- Do you have enough projects to supply all available resources with a suitable workload?

- Do you have enough time to carry out projects with the available resources?

- Do you have the money to carry out all the projects?

You can measure this in terms of people, machines, money, or any other resource that is necessary to deliver a product or service.

Capacity management aims to identify and eliminate bottlenecks during manufacturing and increase the speed of production by optimizing the available resources and removing time and capacity constraints to achieve maximum profit.

So if your business has a limited number of hours from a few of your resources, then the objective is to maximize the value gained within those limits to make sure that your business optimizes its capacity to the fullest.

Now that you know what exactly capacity management is, let’s try and understand why it is important for your business!

Importance of Capacity Management

Having a strong capacity management strategy will bring many benefits to your company. Here are some of the key positive aspects that will it change:

1. Increases Profits

With capacity management, you can identify which parts of your business are not optimized and remove the bottlenecks, thereby saving money and reducing the overall cost of doing business.

It also helps you accurately predict and accommodate future demands that enable you to produce and sell more products, which helps increase your profits.

Read more: What Is Change Management And How To Cope With It?

2. Maximizes Efficiency

Capacity management helps allocate better human and material resources and manage inventory.

It enables the business to grow by providing an in-depth understanding of how to plan production cycles in advance and also helps increase the speed of production by optimizing the available resources and removing time constraints. This results in maximizing production efficiency.

3. Improves Customer Service

With proper capacity management in place, there will be no bottlenecks, constraints, missed deadlines, and delivery delays.

It ensures businesses have the output to meet customer demand so that they can avoid these issues. This helps you offer better customer service.

4. Enhances Competitiveness

Businesses must be able to adapt quickly to the changes in the market if they wish to stay competitive and capacity management allows for this sort of flexibility.

It monitors the costs and shifts, especially during growths or recessions, and lets you act accordingly. It also ensures that your business has the ability to meet customer demand so that you can maintain a competitive edge and achieve business success.

5. Reduces Business Risk

Capacity management focuses on laying down a carefully planned output that aligns with your company’s overall business strategies and goals. This ensures that there is no lack of planning and organization, thereby helping you avoid all possible business risks

Now that you know the various benefits that capacity management comes with, let’s go over the steps involved in carrying out an effective one for your business!

Capacity Management Process in 7 Steps

1. Collect Metrics

A crucial step in the capacity management process is to gather different metrics. After all, a good capacity management process is the combination of a range of different metrics.

These metrics include:

- Resource utilization levels – Helps measure the individual capacity of resources, which means that it shows how well they are being utilized compared to their total potential output. This metric denotes a higher cost if not fully utilized.

- Capacity against demand – This metric ensures that a business is capable of supplying its market without wasting resources or meeting demands.

- Bench management – This refers to the availability of resources for new projects or tasks. Resources on the bench mean that they’re not being utilized currently.

- Forecast time against actual time – This metric compares forecast time for a task against the actual time it took to complete to present better and more accurate time forecasts in the future.

These metrics can be used to get an idea of the demand for production in the coming days and months so that the capacity can be effectively managed.

So if more people need to be hired or machine maintenance is required, it will help you understand and match the upcoming demand.

2. Gather Data

A capacity management plan must include details of the current capacity levels of a company, in general, and in terms of their financial, human, and IT capacity.

It is also necessary to consider whether there are business changes, upcoming projects, regulatory changes, potential technological developments, and contractual commitments that may have an impact on the company’s capacity.

Collect historical data about the past capacity management issues that you had to face and identify any patterns that have formed. For example, a particular area or a particular season that has been consistently causing trouble.

Another way to look for effective capacity management is by reviewing external resource factors, like team members you hire, to keep track of their availability, work hours, and cost rates.

You can also review and manage operational factors that can impact how you manage your work capacity.

3. Analyze Data and Calculate Capacity

Now that you have gathered enough data, you need to get insights into your assets and resources to truly understand what is going on.

Here you need to get a clear idea of the current capacity of your resources, what skills you’ll have in the future, and how much time you will need to adjust to those skills.

For this, you’ll need to have a utilization report to figure out any expected shortages of resource capacity in your company. You can analyze your data from several perspectives:

- Visibility – Analyzing your data to get insights into what resources and assets you have and where they are located.

- Baselining – Creating baselines and profiles of normal utilization by using machine learning to analyze data. This also helps identify cyclical behaviors and typical usage patterns.

- Peak analysis – Studying the changes in workloads and when they occur to make better decisions and improve efficiency and performance without wastage of resources.

- Optimization – Adjusting or modifying the use of resources on a regular basis through automated analysis and recommendations to keep up with the pace of change in the modern business world.

Based on these, you can let teams focus on what’s important, allocate capacity on the basis of business priorities, and define a capacity management strategy for your company.

Read more: Best Resource Management Tools and Software!

4. Monitor Business Demand

Understanding the relationship between current and future demand and how you can manage your infrastructure is an essential part of capacity management.

For this, you need to monitor and analyze customer demand and opportunities and also keep tabs on the market trends across various seasonal changes and other external factors. This ensures that the supply of resources is in accordance with the demand.

5. Evaluate Existing Output

Before increasing production under the new plan, you must evaluate and determine whether your company’s existing infrastructure and resources are capable of managing production.

Depending on the scope of the project, you can see which resources you already have and which are still missing. You must try to determine the most efficient usage of your existing infrastructure so that you can improve performance while keeping spending at current levels.

6. Implement Capacity Planning

Capacity planning is used to determine the resources needed to meet customer demands. You can do this via predictive analysis, benchmarking, modeling, and other techniques.

Once the plan is created, you must implement and execute it properly. If your company requires more machinery and workforce to increase production, then you must purchase or lease new machines, get more workforce to operate them, and start production to meet the customer orders and demands.

Make sure to plan for different scenarios as businesses contain several variables that affect the capacity in different ways. So you need to understand the various risks and be prepared for them with efficient solutions.

7. Monitor and Review

Lastly, it is extremely crucial that you constantly monitor and review your capacity management process. After all, it is an ongoing process and there is always room for improvement.

So after the planning is implemented, you need to continuously keep an eye on your company’s performance and update it regularly.

Conclusion

Ensuring that there is a proper capacity management process in place can be truly effective for your organization in terms of revenue, efficiency, and productivity.

That’s why, in this blog, we have helped you learn everything you need to know about capacity management, its benefits, and the processes involved.

Use this blog as your handy book to help out with your organization’s capacity management! Good luck!

Marketing Project Management: Definition, Process, Tips & More!

9 Best Campaign Management Tools & Software in 2022

Top 9 Inventory Management Software of 2022

9 Risk Management Tools & Techniques You Must Try!

Marketing Management: What is it, its Importance, and its Process!

Stakeholder Management: Definition, Importance & Process!

Related posts

Bit.ai | Watch to Learn More

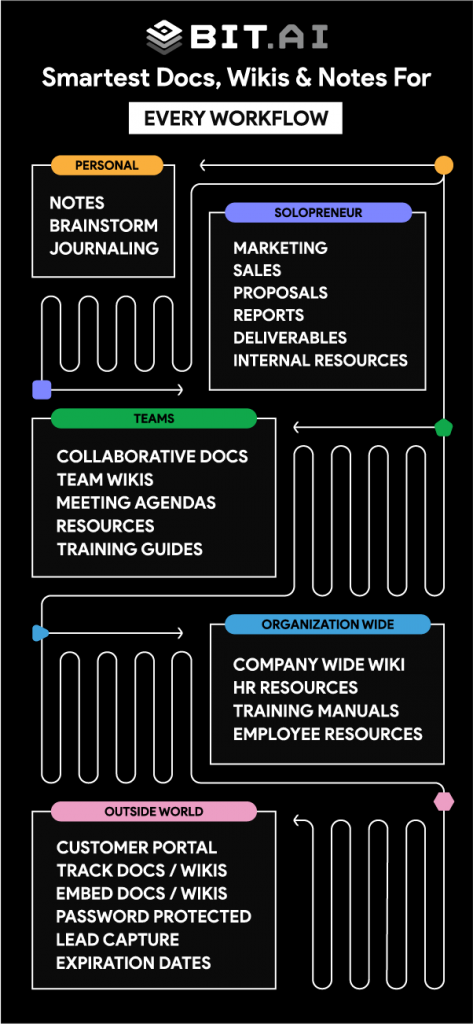

What is Bit.ai?

Bit.ai is an innovative AI-driven knowledge and Document Managment suite designed to empower knowledge workers by streamlining the creation of, documents, wikis, and notes. With an intuitive interface and seamless integration, Bit.ai acts as a versatile assistant to help you collaborate, generate, organize, and visualize your ideas effortlessly. Whether you are drafting a report, managing a project, collaborating with your team or clients, or brainstorming new concepts, Bit.ai brings intelligence and creativity to every aspect of your work process.