You’re working in a massive factory that produces cars. There are countless machines, tools, and processes involved in turning raw materials into shiny new vehicles. Now, picture a veteran worker who knows every nut and bolt of the operation. This person can fix any problem, streamline any process, and find any part in seconds. Their experience and know-how are invaluable, right?

But what happens when that expert retires or moves to another job? If all their knowledge is left with them, the factory might struggle to maintain its efficiency and quality. This is where knowledge management in manufacturing comes into play.

Knowledge management is a buzzword that’s capturing the attention of many industries, especially in manufacturing. It’s all about how companies handle the vast amounts of information they generate and, more importantly, how they leverage the invaluable expertise of their employees. This system would ensure that when an experienced worker retires, their wisdom stays behind, ready to help the next person. That’s the essence of knowledge management in manufacturing.

In this blog, we’ll explore how capturing and managing information can revolutionize a manufacturing environment. We’ll look at common challenges where effective Knowledge Management makes a significant difference. You’ll likely recognize some of these situations from your own experiences.

What is Knowledge Management?

Knowledge management (KM) is the process of creating, sharing, using, and managing knowledge and information within an organization. It’s essentially a way to capture the collective wisdom of your employees and make it accessible to everyone. This can include things like:

- Documenting procedures and best practices

- Sharing lessons learned from past projects

- Connecting employees with expertise in specific areas

- Creating a central repository for information

The goal of knowledge management is to improve efficiency, decision-making, and innovation within an organization.

Benefits of Knowledge Management in Manufacturing

In today’s competitive manufacturing landscape, a company’s greatest asset isn’t just its machinery or materials but its knowledge. Knowledge management (KM) offers a powerful approach to capture the expertise of your workforce and translate it into tangible benefits. Here’s a look at some of the key advantages:

1. Centralized Information

In manufacturing, where precision, efficiency, and speed are critical, having centralized information means that all the teams can work more cohesively. Engineers can quickly find the latest design specifications, production teams can easily access up-to-date operating procedures, and managers can effortlessly track performance metrics.

With a well-organized knowledge repository, employees can easily review past projects, learn from previous mistakes, and build upon existing ideas. This can lead to creative solutions and improvements in manufacturing processes, driving the company forward in a competitive market.

2. Knowledge Retention

Your manager, who’s been with your company for over three decades, is set to retire next year. He’s the go-to person for everything from troubleshooting complex machinery issues to understanding the nuances of your production processes. His wealth of knowledge and experience is invaluable, but what happens when he leaves? All that expertise could walk out the door with him, leaving a significant gap in your operations.

Knowledge management system as a safety net that catches all the best practices, lessons learned, and innovative solutions developed over the years. For example, think about a new worker trying to operate a complex machine without proper guidance. The learning curve becomes much smoother if the knowledge of handling that machine is well-documented and easily available. They can quickly get up to speed and contribute effectively, minimizing downtime and reducing the risk of errors.

Moreover, in manufacturing, technology, and methods are always evolving. Knowledge retention means that the valuable insights gained from years of experience aren’t lost but are instead used to train new employees and improve processes continuously.

3. Standardized Processes

Efficiency and quality are paramount in manufacturing. Standardizing processes is a proven way to enhance both. Knowledge management supports standardization by providing a centralized place for storing and sharing process documentation. It helps identify best practices and areas for improvement, enabling manufacturers to implement changes quickly. This leads to better communication and coordination between departments, reduced waste, and improved quality control.

4. Minimizing Information Overload

In a data-rich environment, it’s easy to get overwhelmed. A good knowledge management system helps combat information overload by making it simple to find relevant information through keyword searches and filters. This is similar to shopping online, where you can quickly find what you need without wading through endless files and folders.

5. Streamlining Training and Development

Knowledge management is like having a well-organized library of everything the company knows. It includes procedures, best practices, troubleshooting tips, and expert advice, all neatly stored and easily accessible.

In manufacturing, where precision, safety, and efficiency are critical, KM can be a game-changer. It helps new employees quickly get up to speed, reduces mistakes, and ensures that everyone follows the same high standards from day one.

Think of KM as the company’s collective brain. When new workers come on board, they can tap into this brain and learn from the experiences and knowledge of their more seasoned colleagues. This makes the training process faster and more effective, as new hires can access detailed guides, instructional videos, and real-time support through digital platforms. They don’t have to rely solely on someone being available to teach them everything in person, which can be slow and inconsistent.

Knowledge Management Use Cases in Manufacturing

Manufacturers leverage KM across various stages of their operations to optimize processes and boost efficiency. Here are some prominent use cases:

1. Product Design and Development

When designing a new product, it’s common to revisit and revise the design multiple times. Each review may bring new insights or necessary changes, requiring updates and adjustments to the product design. This iterative process can involve many people, each contributing their expertise and suggestions.

Without a KM system, team members might create their own versions of documents or design files. This can lead to confusion, errors, and inefficiency, as it’s challenging to track which version is the most current or accurate. A KM system solves this problem by offering a single, centralized location for storing and managing all relevant information. This ensures that everyone is working on the same version of the document or design, reducing the risk of errors and improving overall efficiency.

Moreover, KM systems support real-time editing and collaboration. This means that multiple team members can work on a product design simultaneously, making immediate updates and seeing changes as they happen.

2. Production and Operations

In manufacturing, keeping things running smoothly is key. Knowledge management (KM) steps up to the challenge by making valuable knowledge readily available on the production floor. Here’s how:

- Standardize Manufacturing Processes: Imagine everyone following the same recipe for production success! KM allows you to document best practices for each step, from setup to quality checks. This ensures consistent quality and efficiency across the board. No more wondering if someone’s doing things the “right” way – everyone has a clear roadmap to follow.

- Reduce Downtime: Production stoppages cost money. KM helps by creating a central knowledge base filled with troubleshooting guides and maintenance procedures. When a hiccup occurs, workers can quickly access solutions, diagnose problems, and get things back up and running faster. This minimizes downtime and keeps production flowing.

- Improve First-Time Quality: Nobody wants to spend time fixing mistakes. KM helps capture and share knowledge on quality control methods and best practices. Workers can easily access information on how to properly inspect products, identify potential defects, and ensure everything meets the highest standards. This knowledge sharing leads to fewer production defects and a better quality end product right from the start.

3. Supply Chain Management

Imagine your supply chain as a complex machine. To keep it running smoothly, you need to know everything about the parts – in this case, your suppliers. Knowledge management (KM) acts as the oil that keeps this machine humming. Here’s how KM can supercharge your supply chain:

- Inventory Optimization: No one wants a warehouse overflowing with unused parts, or a production line halted due to missing materials. KM allows you to utilize historical data on demand alongside insights from departments like production and sales. By analyzing this combined knowledge, manufacturers can optimize inventory levels, reduce storage costs, and ensure they have the right amount of materials on hand to avoid production delays.

- Improved Supplier Collaboration: A strong supply chain is a team effort. KM facilitates knowledge sharing with your suppliers. They can access information about your production requirements and quality expectations while you can gain insights into their capabilities and potential bottlenecks. This open communication improves transparency and overall supply chain efficiency, creating a win-win situation for everyone involved.

4. Customer Support and Service

Ever get stuck on hold with customer service, only to finally talk to someone who needs to look up the answer anyway? Manufacturing can avoid that frustration with a knowledge management (KM) system. Here’s how it keeps customer service running smoothly:

- One-Stop Shop for Answers: Imagine a central library for everything customer service needs. Product manuals, frequently asked questions, troubleshooting guides, even repair instructions – all in one easy-to-find location. This empowers customer service reps to quickly answer your questions, saving you time and getting you back up and running faster.

- Technicians as Problem-Solvers: Field service technicians are the heroes who fix things on-site. By equipping them with a KM system on a tablet or laptop, they have instant access to the latest repair procedures and troubleshooting steps. This translates to faster repairs for you, less back-and-forth for them, and, ultimately, a happier customer experience.

- Turning Feedback into Action: The best part? A KM system doesn’t just store information, it gathers it too. Comments and suggestions you provide can be easily collected and analyzed. This valuable feedback helps manufacturers identify areas for product improvement and ensure their service offerings are always meeting your needs.

Challenges and Solutions for Knowledge Management

In manufacturing, keeping all the right information flowing smoothly can be tough. Here are some common challenges and solutions:

- Information Overload: Manufacturing generates tons of data every day. It can be hard to sift through all of it to find what’s useful. Solution: Use software that sorts and organizes data automatically so workers can find what they need quickly.

- Knowledge Silos: Sometimes, different departments or teams keep their information to themselves. This makes it hard for everyone to work together effectively. Solution: Encourage teams to share information regularly through meetings or digital platforms.

- Employee Turnover: When workers leave, they take their knowledge with them. It’s important to capture and save their expertise before they go. Solution: Create databases or documents where employees can record what they know so it’s not lost when they leave.

- Training New Employees: Teaching new hires everything they need to know can take time and resources. Solution: Develop comprehensive training programs that cover all aspects of the job, using both hands-on learning and digital resources.

- Technological Changes: New technologies are always emerging in manufacturing. Keeping up with these changes and integrating them into existing systems can be challenging. Solution: Invest in ongoing training for employees to learn new technologies and update systems regularly.

- Quality Control: Ensuring consistent quality across products requires detailed knowledge and monitoring. Solution: Implement robust quality management systems that include clear standards and procedures for testing and inspection.

Addressing these challenges requires a strategic approach that involves not only technology but also cultural and organizational changes. So far, we have covered the benefits of using a knowledge management system, explored its challenges, and how to tackle them. Now, we will introduce a tool that will be a perfect fit for your knowledge management needs.

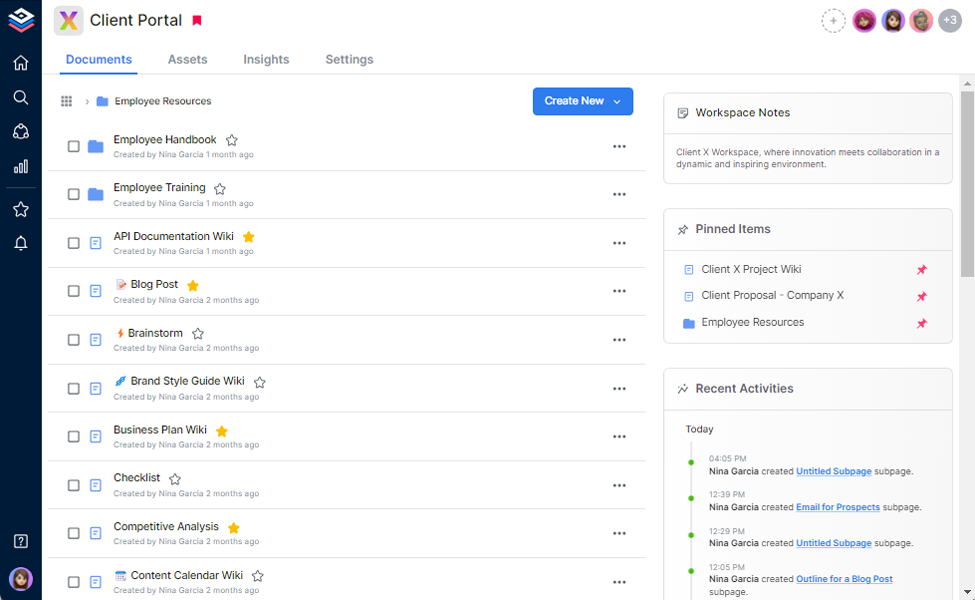

Use Bit.ai for Your Knowledge Management Needs

Bit.ai is an AI-powered innovative tool designed to simplify knowledge management, collaboration, and document creation. It offers a comprehensive solution for teams and individuals to create, share, and organize dynamic documents and wikis with ease. Here are some of the features of Bit.ai:

- Workspace: Consolidate all your manufacturing know-how – procedures, troubleshooting guides, best practices – into a single, searchable platform. No more hunting through dusty manuals or relying on tribal knowledge.

- Real-Time Collaboration: With knowledge management systems, manufacturing teams can work on documents together in real-time. Multiple people can update the same document simultaneously, and you can leave comments or tag others to keep the workflow smooth.

- Smart Editor: The editor in knowledge management systems is intuitive and user-friendly. It helps you create and format documents effectively, with features like text formatting, linking information, creating tables, and more.

- AI Assistance: Some knowledge management systems offer AI-powered tools that assist with tasks like data analysis, research, and generating ideas. It’s like having an intelligent assistant available whenever you need it.

- Smart Widgets: These systems provide useful widgets that allow you to integrate various digital content into your manufacturing documents, such as images, files, tables, and code snippets.

- Create Smart Wiki: Transform any document into a structured knowledge base with the smart wiki feature. You can categorize information into sections and link them for easy navigation and reference.

- Integration with other apps: Bit.ai works seamlessly with over 100 other apps, letting you embed content like Google Sheets, social media posts, and more directly into your documents.

- Multiple Sharing Options: Share your Bit.ai documents in various ways, from live document sharing to embedding them on websites. You can even create trackable links with custom settings like password protection and expiration dates.

![]()

In short, Bit.ai can be your one-stop shop for managing all your manufacturing knowledge. Ready to take your manufacturing knowledge management to the next level? Try Bit.ai today!

Further Reads:

Knowledge Management: What is it & it’s importance!

Essential Free Manufacturing Templates for Production & Operations

Top Knowledge-Sharing Practices to Maximize Manufacturing Performance

Top Knowledge Management Examples for Business Productivity!

Knowledge Sharing Platform vs Knowledge Base: The Key Differences!

Internal Knowledge Base – A Quick Guide by Bit.ai