Let’s consider a scenario.

You noticed that your car has low engine oil. You add more oil to the car to keep your engine lubricated. A week later, your car’s engine oil level dips again, so you just top it off with more oil.

Well, a few days later, you notice that the oil has run low – again. You think to yourself, “What am I doing wrong?” Well, let us tell you what you’re doing wrong. All this time, you’ve just been treating the symptom.

You kept spending time and money to keep your oil levels on point. What you should have done instead was take your car to the mechanic who could’ve investigated the root cause behind the low oil levels in your car.

The moral of the story is: getting to the root cause of the issue, aka conducting a root cause analysis, would fix your engine, and you will not run low on oil ever again!

According to the root cause analysis (RCA) method, it’s more effective to resolve problems by addressing the root cause, rather than just the symptoms.

Root cause analysis is an extremely common – and important concept in all industries. It helps in uncovering why something went wrong before it has a domino effect on the organization.

In this blog post, we will walk you through everything you need to learn about root cause analysis – from what it is to how it works. Ready? Let’s go!

What is Root Cause Analysis? (Definition)

Root cause analysis, commonly known as RCA, is the method of investigating the underlying cause of a problem so that appropriate measures can be taken to prevent the problem from arising again.

The appropriate measure chosen will be the one that is the simplest or least expensive, and one that doesn’t trigger a new root cause, leading to a new problem.

Root cause analysis is a ‘reactive’ process – as it is performed after an incident occurs. However, once RCA is done, it becomes a ‘proactive’ process, as it helps in predicting problems before they occur.

While the term ‘root’ cause implies that every problem has a single cause, it isn’t always the case. Problems might have one root cause or multiple causes – from the failure of materials to a human error.

So, it’s possible that finding and fixing one root cause will not eliminate a problem completely. In such scenarios, RCA might be conducted on a recurring basis to eliminate the series of issues.

To better understand what exactly root cause analysis is, let’s take an example: Company X finds out that their baby stroller has a high return rate, as one wheel of the stroller often falls off.

After conducting RCA, Company X finds out that the nut used to tighten the wheels isn’t the right one for the stroller. So, they buy the correct nuts from a supplier.

As a result, the return rate of the stroller reduces but doesn’t entirely go away. After conducting another RCA, the company discovers that, sometimes, the axle onto which the nut is tightened breaks off too. Now, they buy the axle component with strict specifications, after which the return issue is totally eliminated.

Now that you know the nitty-gritty of what root cause analysis is, let’s head over to the next section and explore the three major types of root causes.

Read more: Competitor Analysis: What is it & How to do it? (Template Included)

What Are The Three Types of Root Causes?

1. Physical Causes

Physical causes aren’t human-made mistakes. These causes arise due to problems in the physical components of the system. Here are some examples of physical causes:

- Hardware failure. (It’s actually one of the most occurring root causes)

- Software stops working due to server failure.

- Material items purchased don’t fit the product.

2. Human Causes

As the name suggests, human causes are human-made mistakes, which lead to physical causes. If someone did something wrong or didn’t do what was required, it leads to human errors and causes. For instance:

- A coding error was caused by the developer.

- A person didn’t have the skill set that was required to perform a particular task.

- A person didn’t have enough knowledge of the tool.

3. Organizational Causes

It isn’t necessary that all the decisions taken by the organization are right. Sometimes, organizations are also responsible for a problem. Here are some examples of organizational causes:

- The manager gave incorrect instructions to his subordinates.

- The wrong person was selected for performing a task.

- There was a scarcity of tools required to finish a project.

Conducting a root cause analysis is extremely important for every industry and organization. Want to know why? Let’s find out!

Why You Should Conduct a Root Cause Analysis?

The major benefit of a root cause analysis is that it identifies the underlying error in the development process, allowing your team to implement the right measures to solve the problem and stop it from happening again. Some other reasons why you should conduct an RCA are:

1. Reduces Costs: If the defects are found later in the development process, the cost of fixing them increases. Most importantly, If a defect makes it into the final product release, the customers might never buy the product again, leading to a loss of revenue.

2. Identifying Failure: If you think that your team has the perfect QA procedures and product development process, and yet you face defects – then obviously there’s a problem. RCA helps you figure out the root cause of the problem. It helps you answer the what, why, and where!

3. Better Customer Experience: When you address the root cause of problems, it shows that your company takes customer reviews seriously, and does everything it can to resolve the issues faced by the customers.

4. Improving Safety & Reliability: Root cause analysis reduces the number of defects that might come up in the future. This is extremely beneficial to the companies that are in quality critical industries, where product safety and reliability are of utmost importance.

5. More Time To Market: By finding the root cause of the problems that have arisen, and taking subsequent measures to correct those problems, will reduce the time taken to test a product. The result? Your product would be released in the market sooner.

We all have heard the three Rs of waste management: ‘reduce, reuse, and recycle’. Well, root cause analysis has its own 3Rs: Recognize, Rectificty, Replicate. Let’s explore each of them!

The 3 Rs of Root Cause Analysis

1. Recognize

The thing is, the real cause of a problem isn’t always visible, and basic fixes usually don’t solve the underlying problem. Even though RSA is a time-consuming process, its goal is to recognize the root cause of a problem, so that we can take the right action and eliminate future problems. As soon as you notice that something isn’t working the way it is supposed to, put on your detective cap and find out what’s happening!

2. Rectify

Once you have identified what the root cause is, start a corrective course of action. If the root cause is addressed, then the problem should not arise again. If the same problem resurfaces, then the cause you identified might not be the actual root cause. In this case, go through the RCA process once again and try your best to identify the actual root cause.

3. Replicate

Good job! You’ve now recognized – and rectified the root cause. The next step is to make sure that it doesn’t happen again at any point during the process. Let’s take an example. Let’s assume there was a problem with particular software, but you’ve now fixed it. To make sure that you’ve actually fixed the root cause of the problem, you can replicate the problem and test it out.

A root cause analysis can be conducted using different methods and techniques. It entirely depends on your industry, the problem, and your preferences. Let’s explore the most popular RCA techniques.

Read more: What is SWOT Analysis: The Complete Guide!

The 4 Most Popular Root Cause Analysis Methods

1. The Five Whys

This method of RCA urges the practitioner to repeatedly ask ‘why’, in order to get to the bottom of the root cause that led to an issue, event, or incident.

Simply asking ‘why did this happen’ might not take you to the root cause of a problem. To identify the cause and corrective steps that need to be taken, you have to go through several layers of questioning.

2. A Fishbone Diagram

This root cause analysis method encourages the practitioner to identify the root cause of a problem from multiple sources. Basically, it helps the investigator get to the root cause quickly, by evaluating the different types of causes that could’ve led to the problem.

3. Failure Mode and Effects Analysis (FMEA)

This method of RCA tries to predict future failures and defects of a machine/system by analyzing data from the past. The ‘failure mode and effects analysis’ method has three main components: quality control efforts, safety engineering, and reliability engineering.

4. Pareto Charts

A Pareto chart is the combination of line graphs and bar charts. It is perfect for identifying the most significant causes of a problem when it has multiple causes.

The factors are shown as bars set in descending order, and a line graph shows the total of each factor – from left to right. A Pareto chart is generally used to identify the most common source of the defect.

The process of root cause analysis varies across industries and organizations. However, let’s explore the steps for the basic framework of RCA.

How to Perform a Root Cause Analysis? (Step-By-Step)

Step 1. Identify the Problem

First things first you need to define the problem statement and symptoms of the problem. It could be a human error, machinery malfunction, or a faulty process. Once you have identified the problem, look over any suspected contributing factors that might stop the problem while you’re trying to find the root cause.

Step 2. Collect Data

Now that the problem is identified, gather as much data as you can, including interviews with anyone who was involved with the issues, screenshots and logs, incident reports, and more. You can use this data to determine the sequence of events and what led to the problem, as well as the overall impact of the problem.

Step 3. Determine The Root Cause

You and the rest of the RCA team can conduct brainstorming sessions to ascertain the root cause. You can use the techniques we’ve listed above – Pareto charts, Fishbone diagrams, etc. Remember – your brainstorming sessions need to be collaborative and you shouldn’t start blaming each other for the problem that occurred.

Step 4. Implement The Solution

It might be possible that the root cause can be solved through multiple solutions. It is the responsibility of the RCA team to ensure which solution is the best, and when it should be implemented. Once the solution has been implemented, it needs to be constantly monitored to ensure that it’s working.

Step 5. Document Your Actions

What’s one of the most crucial aspects of RCA? It is to prevent the problem from happening again. Always document the problem and the best solutions, so that teams can refer to it in the future. You can also include preventative actions in the document, as well as recommendations for improvements.

Wrapping Up

Root cause analysis helps you identify problems and come up with solutions quickly and accurately. RCA is so important and effective that it is actually mandatory in numerous industries!

Yes, establishing a solid RCA process takes a significant amount of time and effort. However, it’s totally worth it. After all, it gives the organization what it needs to perform the best.

We know that there’s a lot of information to digest here, so if you have got any queries, concerns, or suggestions – tweet us @bit_docs and let us know. Cheers!

Further reads:

How to Write a Business Case: Step By Step Guide

Gap Analysis: Definition, Techniques & How to Perform it?

Incident Report: What is it & How to Write it the Right Way!

Related posts

Bit.ai | Watch to Learn More

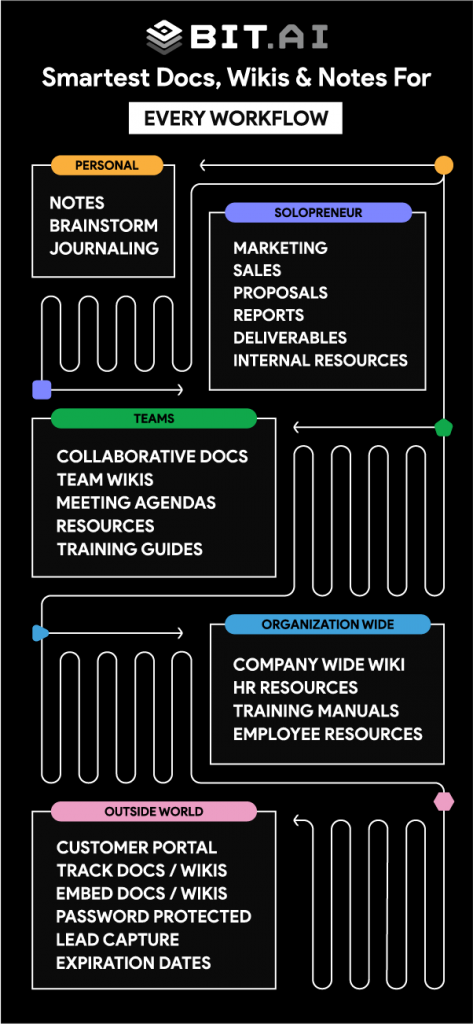

What is Bit.ai?

Bit.ai is an innovative AI-driven knowledge and Document Managment suite designed to empower knowledge workers by streamlining the creation of, documents, wikis, and notes. With an intuitive interface and seamless integration, Bit.ai acts as a versatile assistant to help you collaborate, generate, organize, and visualize your ideas effortlessly. Whether you are drafting a report, managing a project, collaborating with your team or clients, or brainstorming new concepts, Bit.ai brings intelligence and creativity to every aspect of your work process.