Imagine your team runs like a well-oiled machine, communicating and handling tasks with ease. But what happens when a key member is suddenly unavailable due to vacation, sickness, or leaving the company? Often, the wheels fall off, and people struggle to find information and complete tasks. This scenario highlights a common challenge: the lack of effective knowledge sharing.

Addressing this issue is crucial for any company that wants to learn and grow. Captured knowledge needs to be shared, scaled up, and replicated to ensure continuous improvement and operational efficiency.

To help you tackle this, we’ll explore best practices for knowledge sharing in manufacturing, boosting productivity and engagement within your team. Dive into our complete blog post where we’ll discuss these strategies in detail and show you how to keep your machine running smoothly.

What is Knowledge Sharing?

Knowledge sharing is when you exchange your learnings, ideas, skills, and experiences with others. In manufacturing, this often means employees from different departments come together to discuss how to improve processes and increase efficiency. This practice is vital because it keeps valuable information from being lost and makes it accessible to everyone.

By sharing knowledge, you can boost productivity, make better decisions, and strengthen your company’s culture. It’s essential to create an environment where knowledge is shared regularly, as storing information isn’t enough. If employees struggle to find the information they need, it can hurt the company’s performance. Therefore, making knowledge sharing a regular part of your workplace is crucial for ongoing success and growth.

Benefits of Knowledge Sharing in Manufacturing

Gone are the days when employees simply followed orders without understanding the technology behind their tasks. Today, modern workers crave insight and innovation. Creating a collaborative workplace is essential, where new hires are eager to learn, and experienced employees can share their expertise.

Knowledge sharing aligns organizational goals with employee learning, boosts engagement, and retains valuable skills. This approach helps identify growth opportunities, avoid knowledge loss, and save time. Let’s explore the benefits of knowledge sharing in manufacturing in this section:

1. Enhances Collaboration and Minimizes Internal Competition

Workplaces sometimes see information as a form of currency, leading employees to hoard knowledge to stand out. This internal competition can hurt overall team success. However, when employees share their advice and lessons learned, this barrier is removed.

Teams start to work together more effectively, building a culture focused on collaboration. This change not only boosts team morale but also ensures that everyone benefits from shared expertise, leading to better overall performance and a more cohesive work environment.

2. Boosts Productivity

When employees keep valuable knowledge to themselves, it costs time and money. Big companies can lose millions annually due to inefficient knowledge sharing. If team members have to spend time hunting down information, projects get delayed.

But when employees share what they know, everyone can access the necessary information quickly. This means less time wasted and faster completion of tasks, leading to higher productivity and significant cost savings.

3. Utilizes Proven Problem-Solving Techniques

In manufacturing, facing problems is inevitable. Sharing knowledge helps utilize proven problem-solving techniques. When experienced employees share their strategies and solutions, others can apply these methods to similar issues.

This exchange ensures that the team can tackle challenges more efficiently, reducing downtime and improving overall productivity. By taking lessons from past experiences, your team can avoid repeating mistakes and continuously improve processes.

4. Encourages Workplace Innovation

Innovation thrives in environments where knowledge is freely shared. In manufacturing, when employees exchange ideas and best practices, they become more aware of new trends and markets. This open communication stimulates creativity and encourages employees to think outside the box.

As a result, the workplace becomes a breeding ground for innovative solutions, leading to improved products and processes. Encouraging this kind of environment helps the company stay competitive and forward-thinking.

5. Prevents Knowledge Loss

Knowledge is a crucial asset for any manufacturing company. When experienced employees leave, they take valuable know-how with them, which can negatively impact the business. Implementing effective knowledge-sharing practices ensures that critical information is captured and made accessible to all employees.

This can include using central communication platforms, maintaining detailed documentation, and regular training sessions. By doing so, the company retains valuable insights and maintains operational continuity, even when key personnel move on.

Best Practices for Effective Knowledge Sharing

As we know, the benefits of sharing knowledge in the workplace are immense, from boosting productivity to preventing knowledge loss. But, how can you enhance knowledge sharing in your organization is the real challenge. In this section, explore our best practices to encourage this vital activity. Read on!

1. Develop Sharing Habits

Creating habits around sharing knowledge is essential for fostering a collaborative culture in manufacturing. It’s not enough to simply educate employees about sharing practices; they need to understand the tangible benefits of learning from each other’s experiences. Establishing a knowledge-sharing culture involves developing a lifecycle of knowledge, which includes building, storing, pooling, and extending knowledge.

Technology plays a vital role in this by aligning internal communication, discussions, and knowledge dissemination. Encouraging regular meetings, training sessions, and collaborative projects can help embed these habits into daily routines. Over time, these practices make it easier for your employees to share insights and solutions, ultimately leading to a more knowledgeable and efficient workforce.

2. Standardize and Document Processes

Having clear and accessible documentation is crucial in manufacturing. Standard operating procedures (SOPs) should be well-documented and easily available to all employees. Regularly updating machinery manuals, maintenance guides, and process documentation ensures everyone has the latest information.

Also, using visual aids like diagrams, flow charts, and videos can simplify complex processes, making them easier to understand and follow. By standardizing and documenting processes, you create a reliable reference that reduces errors and training time. This practice not only helps new employees get up to speed quickly but also ensures that all team members perform tasks consistently and correctly.

3. Use a Knowledge-Sharing Platform

Selecting the right knowledge-sharing platform can significantly impact productivity and business performance in manufacturing. A good platform enables quick content searches, easy storage of documents and media, and efficient sharing of knowledge within the organization. It also allows your employees to ask questions and share answers easily.

By implementing an effective knowledge-sharing tool, you can align business processes and maximize the value of contributions from every team member. These platforms support your organization in keeping valuable information accessible and up-to-date, fostering a culture of continuous learning and improvement. This, in turn, leads to enhanced efficiency and innovation across the company.

4. Reward Knowledge Sharing

Giving employees a good reason to share knowledge is essential for fostering a culture of collaboration in manufacturing. Rewards are a powerful incentive and don’t have to be always expensive. In fact, 85% of employees appreciate a simple ‘thank you,’ whether written or verbal, over physical gifts.

Public recognition, such as a social media post on the company page, an appreciation email, or an announcement, can also motivate your employees. Highlighting the specific content shared and its tangible benefits encourages everyone to contribute. Also, consider offering bonuses for employees who share the most valuable information during the quarter or year.

5. Use Different Sharing Formats

Knowledge in manufacturing can be shared in many ways, and using different formats can make this process more effective. Encourage employees to document their tasks in simple steps and provide additional tips or explanations.

This ensures that anyone can replicate the work accurately. However, don’t limit yourself to written documentation. Embrace digital tools that allow quick updates and real-time viewing, reducing the risk of outdated information. Consider using:

- Videos for demonstrations or tutorials

- GIFs for quick, visual instructions

- Graphics with key information

- Interactive training sessions

Uploading internal documents to specialized software can enhance document sharing and collaboration. These diverse formats cater to different learning styles and help improve information retention.

By making knowledge accessible in various ways, you ensure that everyone in the organization has the current information they need, leading to better productivity and innovation.

6. Revise Onboarding Processes

Setting the tone for knowledge sharing from the start is crucial. Look at your onboarding process and find ways to integrate more opportunities for knowledge exchange beyond manuals and paperwork. Incorporate presentations from different departments so new hires understand the bigger picture and meet people outside their immediate team.

Allow new hires to rely on experienced employees to learn insider tips not covered in formal training. Pairing new hires with a mentor or buddy, even from a different department, provides a go-to person for questions and challenges. This buddy system is highly effective; a Human Capital Institute report found that 45% of companies using this system saw it as slightly or extremely effective in speeding up new hire proficiency.

7. Encourage Cross-Department Collaboration

Breaking down silos between departments enhances knowledge sharing in manufacturing. Encouraging employees to work together on projects or problems helps them understand different perspectives and areas of expertise. Regular cross-departmental meetings or brainstorming sessions can spark new ideas and solutions.

Joint training sessions and workshops allow your employees to learn from each other and build a shared knowledge base. Creating task forces with members from various departments for specific projects can also promote collaboration. By fostering an environment where employees from different areas regularly interact and share their insights, you can benefit from a more cohesive and innovative workforce.

8. Request Feedback

The simplest way to understand how to make employees more comfortable with sharing knowledge is to ask them directly. You can do this through one-on-one conversations, group sessions, focus groups, or surveys. Consider questions like:

- How comfortable are you sharing your ideas with team members?

- What makes you hesitant to share knowledge or ideas?

- What can we do to encourage more knowledge sharing?

Asking for feedback helps employees voice their opinions and build a culture where everyone feels included, valued, and heard. Regularly gathering input not only shows that their opinions matter but also provides practical insights into improving knowledge-sharing practices. By involving employees in this process, you can identify and address barriers to knowledge sharing more effectively and quickly.

9. Create a Safe Sharing Environment

To encourage a culture of sharing insights in manufacturing, it’s crucial to create an environment where employees feel safe to ask questions and make mistakes. This concept, known as team psychological safety, was introduced by Amy Edmondson, a Professor of Leadership and Management. She describes it as a workplace where people are not afraid of being embarrassed or punished for speaking up.

In such an environment, employees can share ideas freely and even fail without fear of judgment. To cultivate psychological safety, explain why everyone’s contribution is important and welcome. Stress the importance of knowledge sharing during onboarding and regularly invite feedback through meetings. Provide various ways for employees to share their ideas and ensure guidelines are in place to handle mistakes constructively.

10. Track and Measure Results

Measuring the effectiveness of your knowledge-sharing practices is essential. You need to know what works and what doesn’t. One way to gauge success is by tracking user engagement. Consider the following metrics:

- Document views: Check how many people are viewing your content.

- Time spent: See if employees find the content useful.

- Comments: Analyze feedback to understand if the information is clear.

For instance, if you post an article, check how many views it gets over time. If views are low, the topic might already be familiar. More time spent indicates that the content is appreciated, while less time suggests issues with the content.

Comments can provide insights into areas that need clarification. Also, measure the time employees spend searching for information. Effective knowledge-sharing should reduce this time, indicating better accessibility and usability of shared knowledge.

Bit.ai: The Ultimate Platform for Knowledge Sharing

Effective knowledge sharing is crucial in manufacturing, but it can often be challenging. Without a centralized, efficient platform, important information can get lost, and collaboration can become disjointed. A modern platform with advanced features can simplify the process, making it easier for teams to share and access information easily.

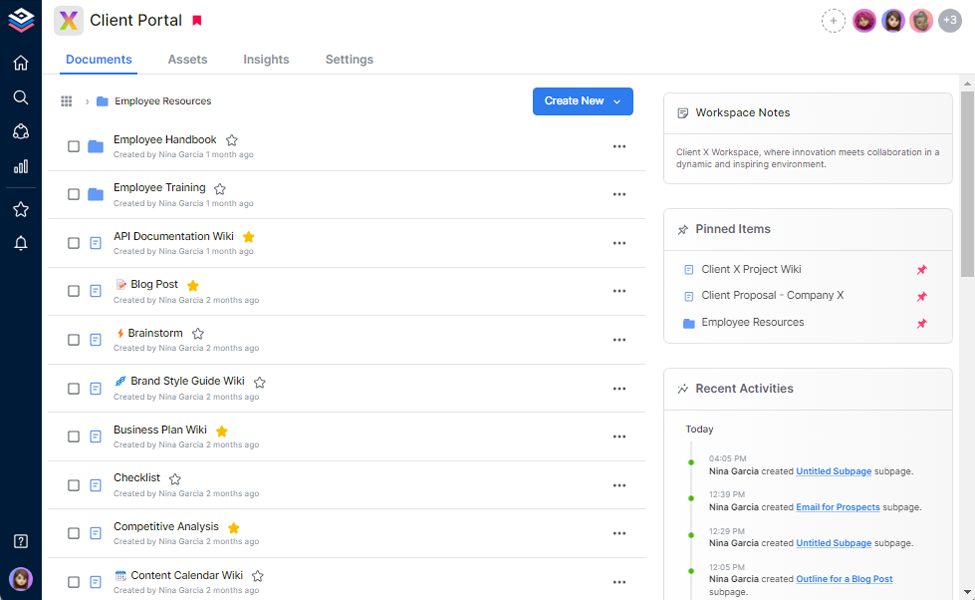

Enter Bit.ai, an AI-integrated, cloud-based document and wiki collaboration platform designed to enhance knowledge sharing. Bit.ai’s powerful features make it an ideal solution for the manufacturing industry, ensuring that valuable insights are easily shared and accessible to everyone. Let’s look at its key features:

1. Smart Workspace

Smart workspaces serve as a central hub for all your manufacturing tasks. Think of it as a digital office where you can store and organize all your documents and data in one place. This makes it super easy to find the information you need.

Whether it’s production schedules, maintenance manuals, or project plans, everything is accessible and neatly organized, ensuring that your team always has the information they need at their fingertips.

2. Real-Time Collaboration

With Bit.ai, you can work on documents together with your team in real-time. Multiple people can edit the same document simultaneously, and you can leave comments or tag others to keep the conversation going smoothly.

This feature is crucial in manufacturing, where timely updates and collaborative problem-solving are essential. Everyone stays on the same page, reducing errors and improving efficiency.

3. Smart Editor

Bit.ai’s smart and user-friendly editor helps you create polished documents with ease. You can format text, add links, create tables, and more. This makes it simple to document processes, create manuals, and share technical knowledge. Clear and well-formatted documents are crucial in manufacturing to ensure that everyone understands procedures and specifications correctly.

4. AI Genius Writer

The AI genius writer in Bit.ai can assist with writing tasks, research, proofreading, translation, and idea generation. It’s like having a helpful assistant ready to help you create content. This feature can save time and ensure that your documentation is thorough and accurate, which is vital in a manufacturing environment where precision is key.

5. Smart Widgets

Bit.ai offers smart widgets that allow you to add various types of digital content to your documents, such as images, files, tables, and code snippets. This enhances your documentation, making it more interactive and informative. In manufacturing, this means you can include diagrams, tables, files, and other technical content directly in your documents, providing a richer and more useful resource for your team.

6. Create Smart Wiki

With Bit.ai, you can turn any document into a smart wiki. Organize your information into subpages, and maintain the content hierarchy for easy navigation. Having a well-organized wiki means that your employees can quickly find the information they need to perform their tasks correctly and efficiently.

7. Integration with Other Apps

You can easily add content directly to your document from over 100 other apps like Google Sheets, Tableau, YouTube, etc. This integration capability ensures that all your tools and data are connected, making information sharing more holistic and efficient.

For manufacturing teams, this means you can combine data from various sources into one cohesive document, aligning workflows and improving access to important information.

8. Multiple Sharing Options

Bit.ai provides multiple ways to share your documents, from live document sharing to embedding them on websites. You can also create trackable links and get insights like the number of views and time spent on documents.

Trackable documents come with custom settings like password protection and expiration dates. This flexibility in sharing ensures that the right people have access to the right information at the right time, which is crucial in a fast-paced manufacturing environment.

![]()

In short, Bit.ai offers a comprehensive set of features designed to enhance knowledge sharing in manufacturing. By integrating Bit.ai into your workflow, you can ensure that valuable knowledge is easily shared and accessed, driving better decision-making and operational success.

Conclusion

We’ve reached the end of our discussion on knowledge-sharing best practices. You’ve learned about what knowledge sharing is, its numerous benefits, and the best practices to implement. An efficient knowledge-sharing platform can significantly enhance these efforts.

By adopting these strategies, you can drive operational success and foster a culture of continuous learning and improvement within your manufacturing team. This will keep your company competitive in a rapidly evolving industry.

So, take action now! Implement these best practices and create a powerful workforce. When your team members are in the habit of sharing insights, they can easily complete the task when someone is away, avoiding last-minute panics. Remember, “Sharing is caring, especially when it comes to knowledge!”

Further Reads:

Knowledge Management Process: A Comprehensive Guide!

Leverage the Power of Knowledge Management to Streamline Manufacturing

How to Encourage Knowledge Sharing in the Workplace?

Essential Free Manufacturing Templates for Production & Operations

Knowledge Sharing Vs Knowledge Management: The Key Differences!

Top Knowledge-Sharing Methods for Enhanced Productivity & Innovation!